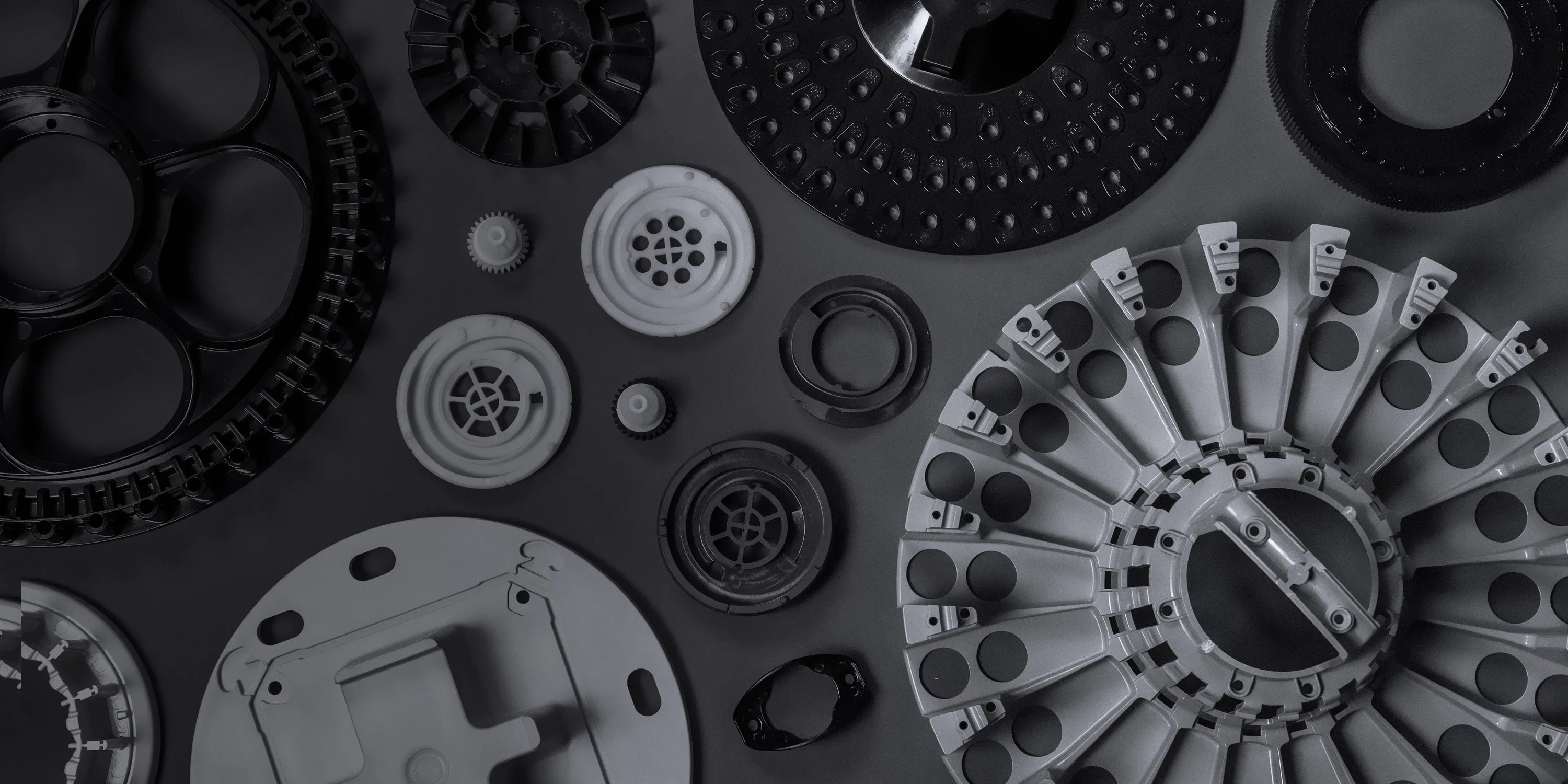

Injection Moulding

Injection Moulding manufacturing in our ISO 9001 Certified facility or in our second ISO 13485 certified facility that is with a 220 m2 cleanroom where we can manufacture products in latest generation injection machines. We manufacture products with very demanding specifications using commodity and high-performance/engineering materials.

Post Processing & Assembly

Forme Technologies is an end-to-end manufacturing company. We provide value-adding post processes for your products. We have available manual and automated assembly services by purposed made machines and/or manufacturing cells with robots. We operate several in-house processes as ultrasonic welding, UV bonding and heat stacking processes.

Product Development

Forme Technologies has a vast experience on taking products as we call it, “from art to part”. Benefit from over two decades of expertise delivering solutions for a broad range of industries such as medical, defence, construction, sports, gaming, automotive, consumer goods and electronics to name a few.

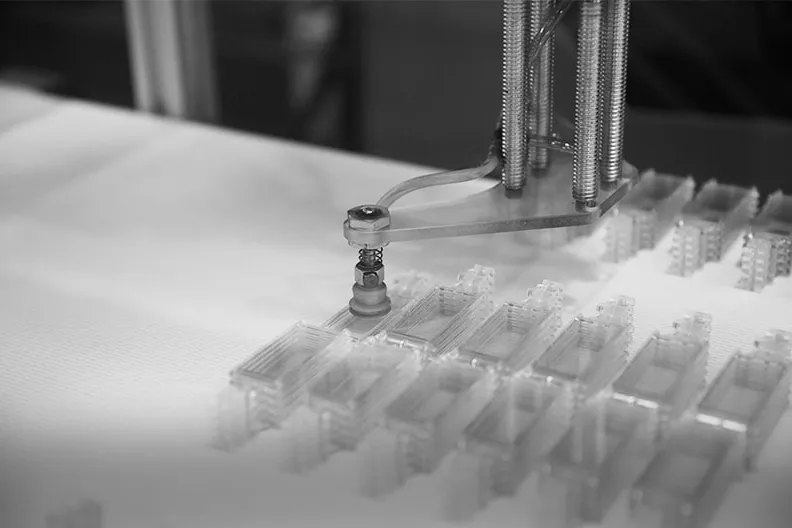

Tooling

Tooling development is the last chance to make sure that the manufacturability, quality, and efficiency to make your products is right. It can make or break a good design. That is why we are constantly assessing whether your design is suitable or can be optimised for the injection moulding process, in an iterative process called DFM (Design for Manufacturing); We do this even from the moment you first approach us.