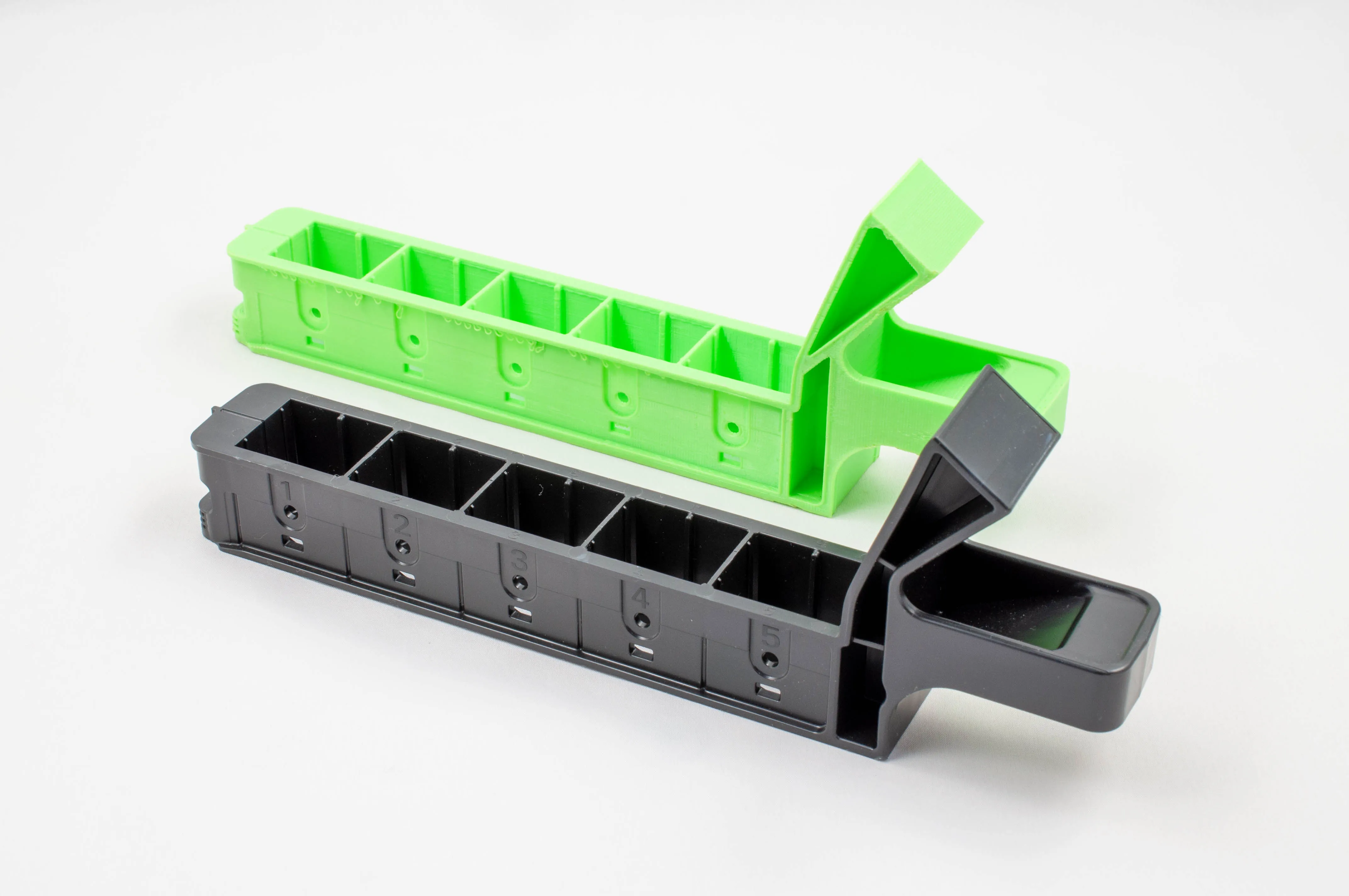

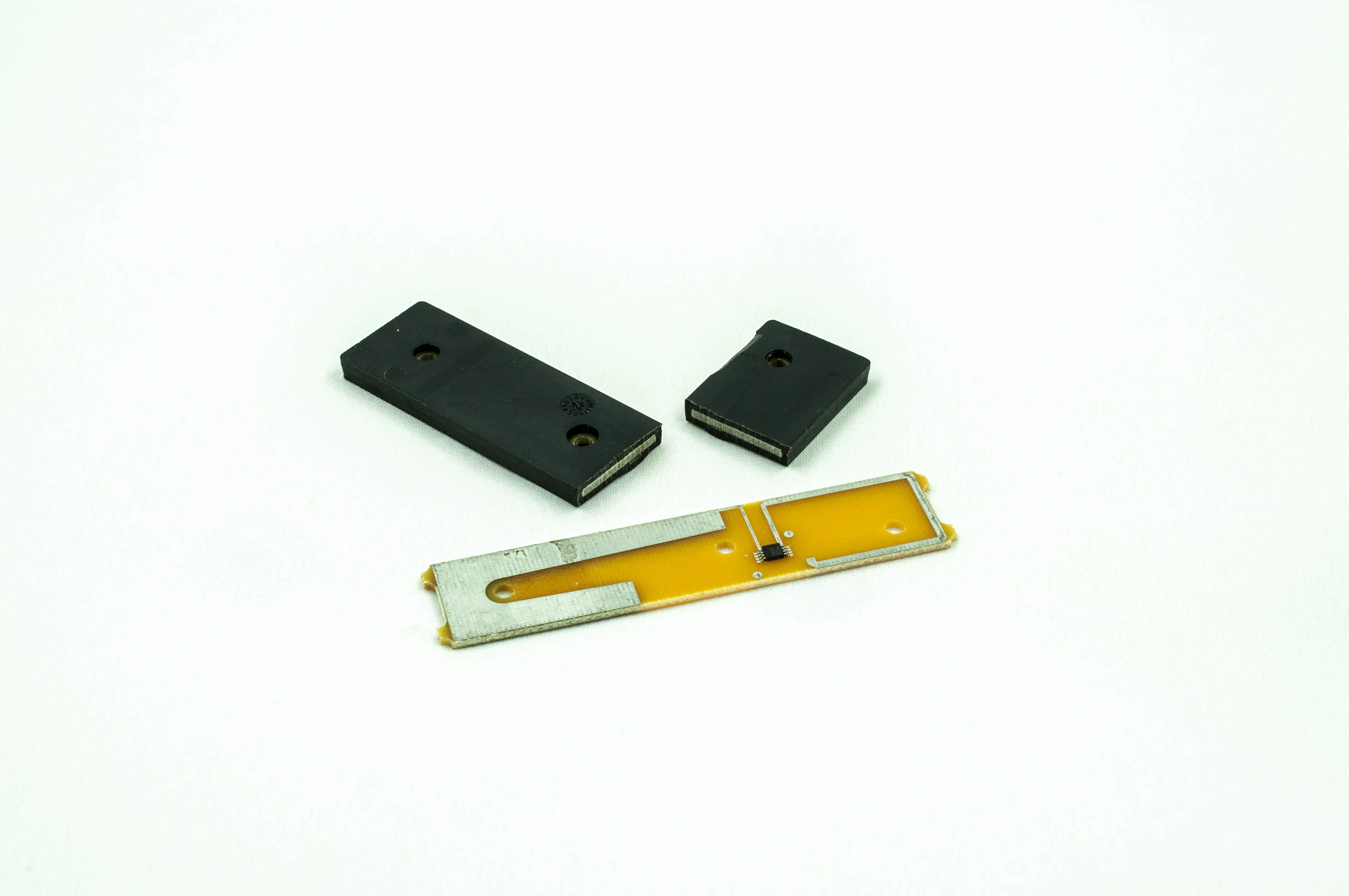

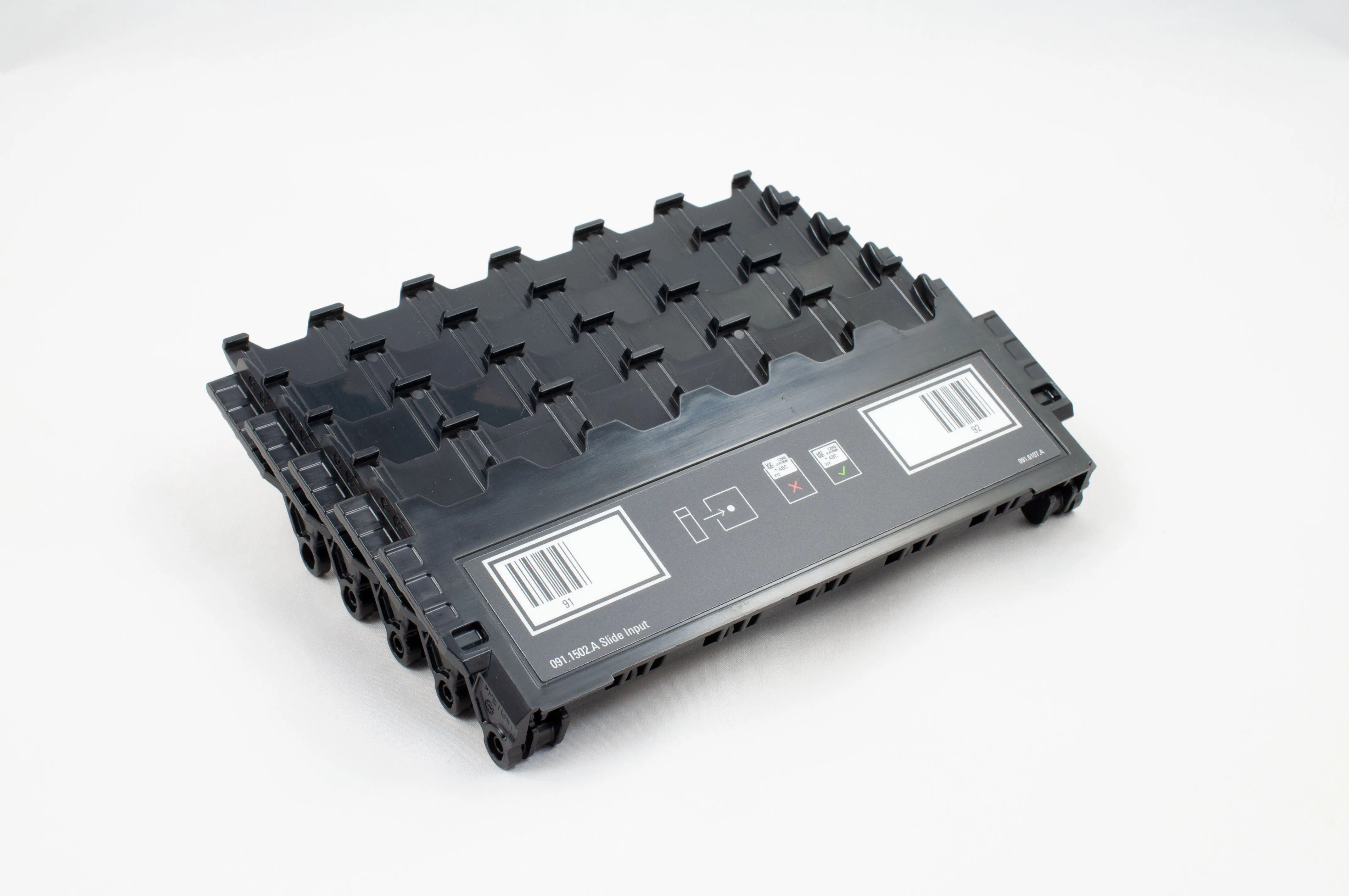

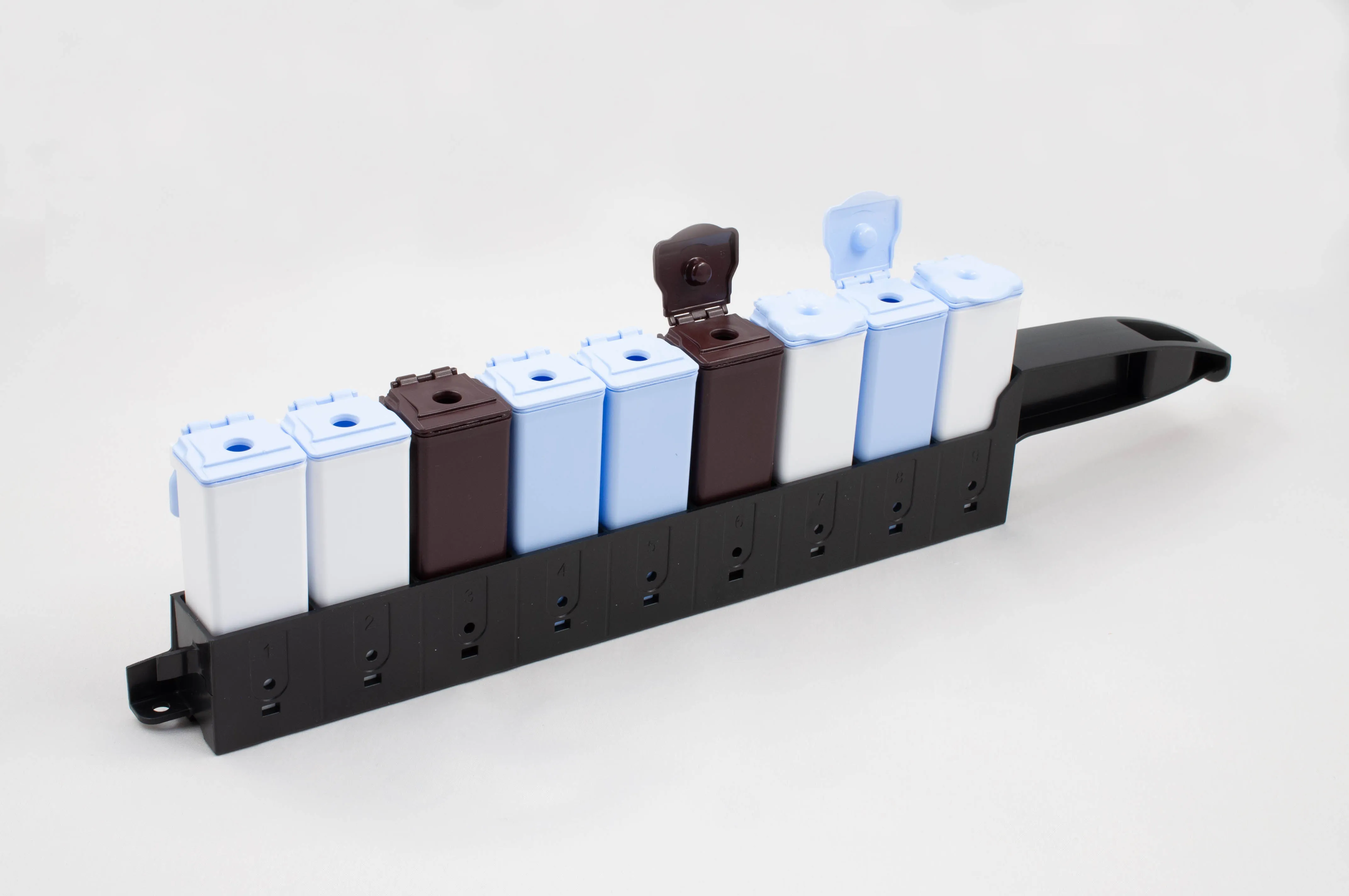

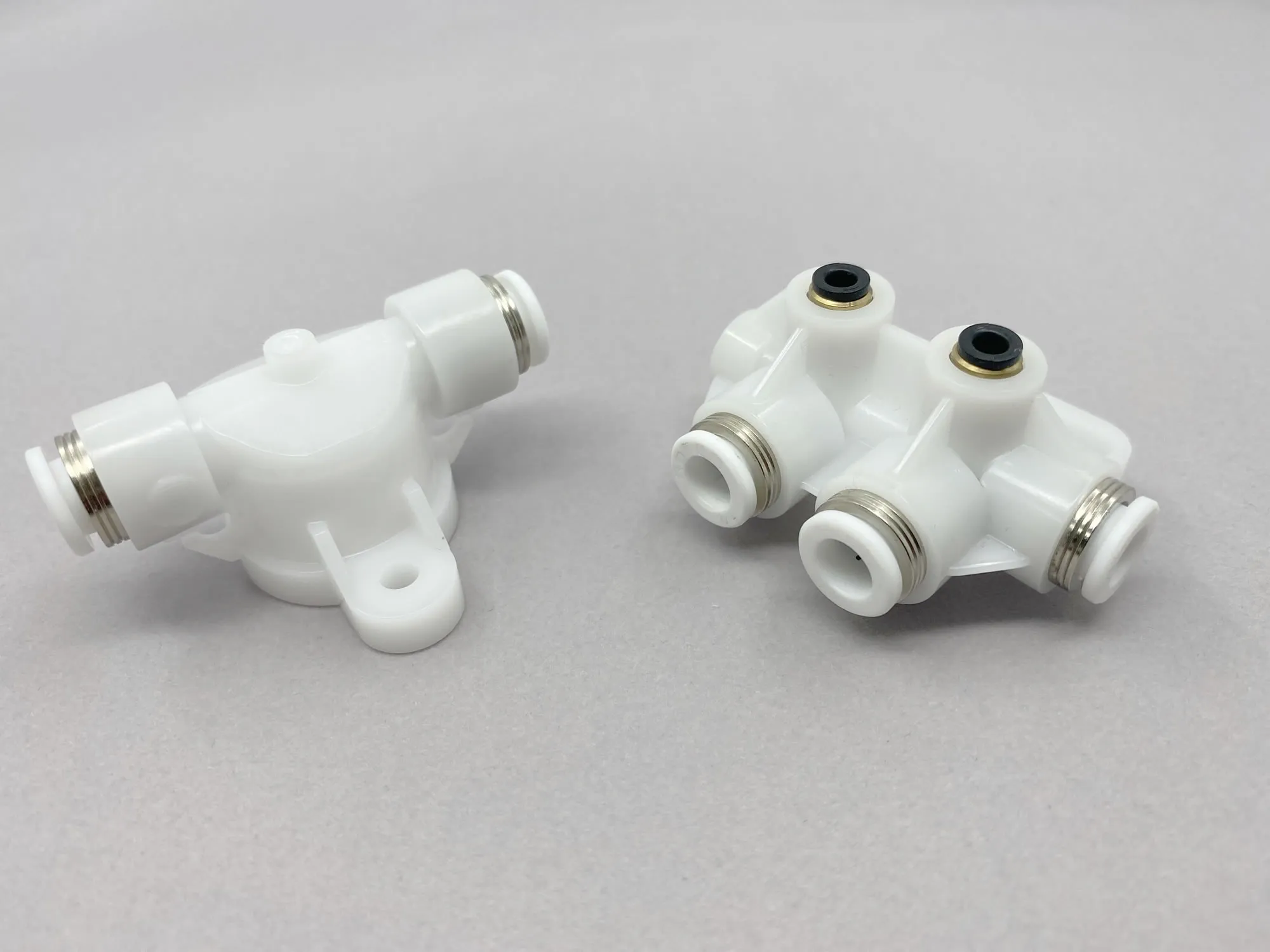

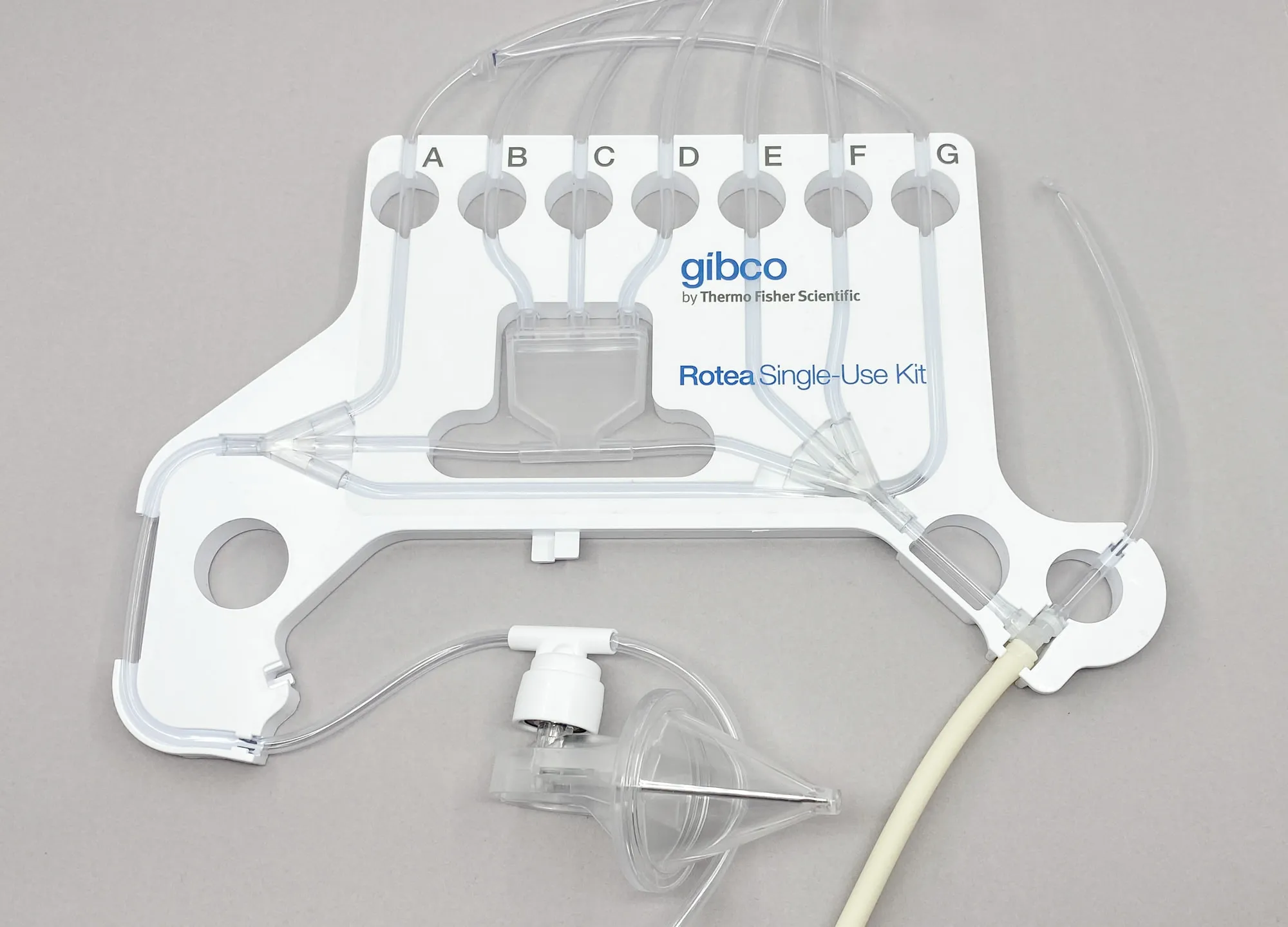

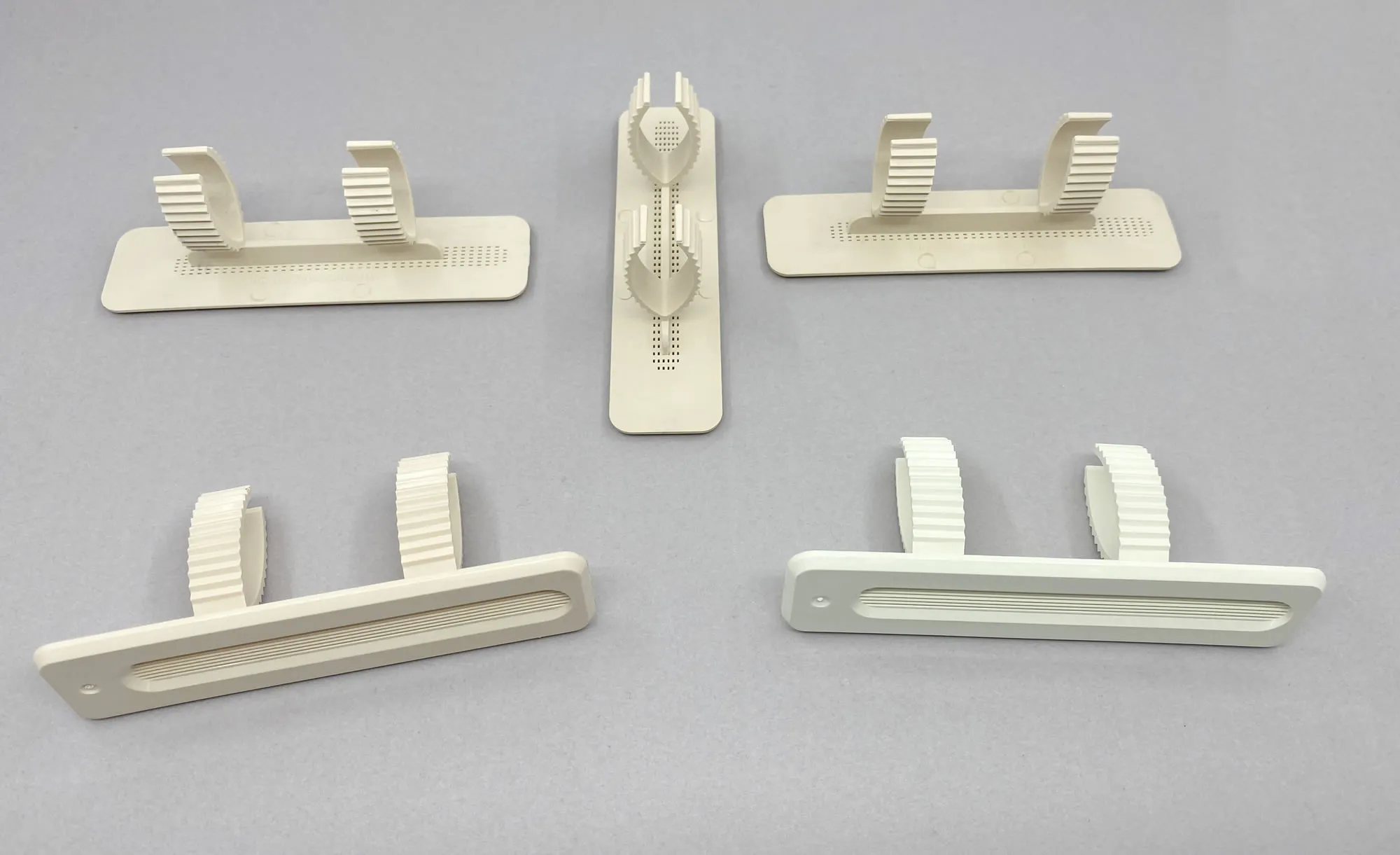

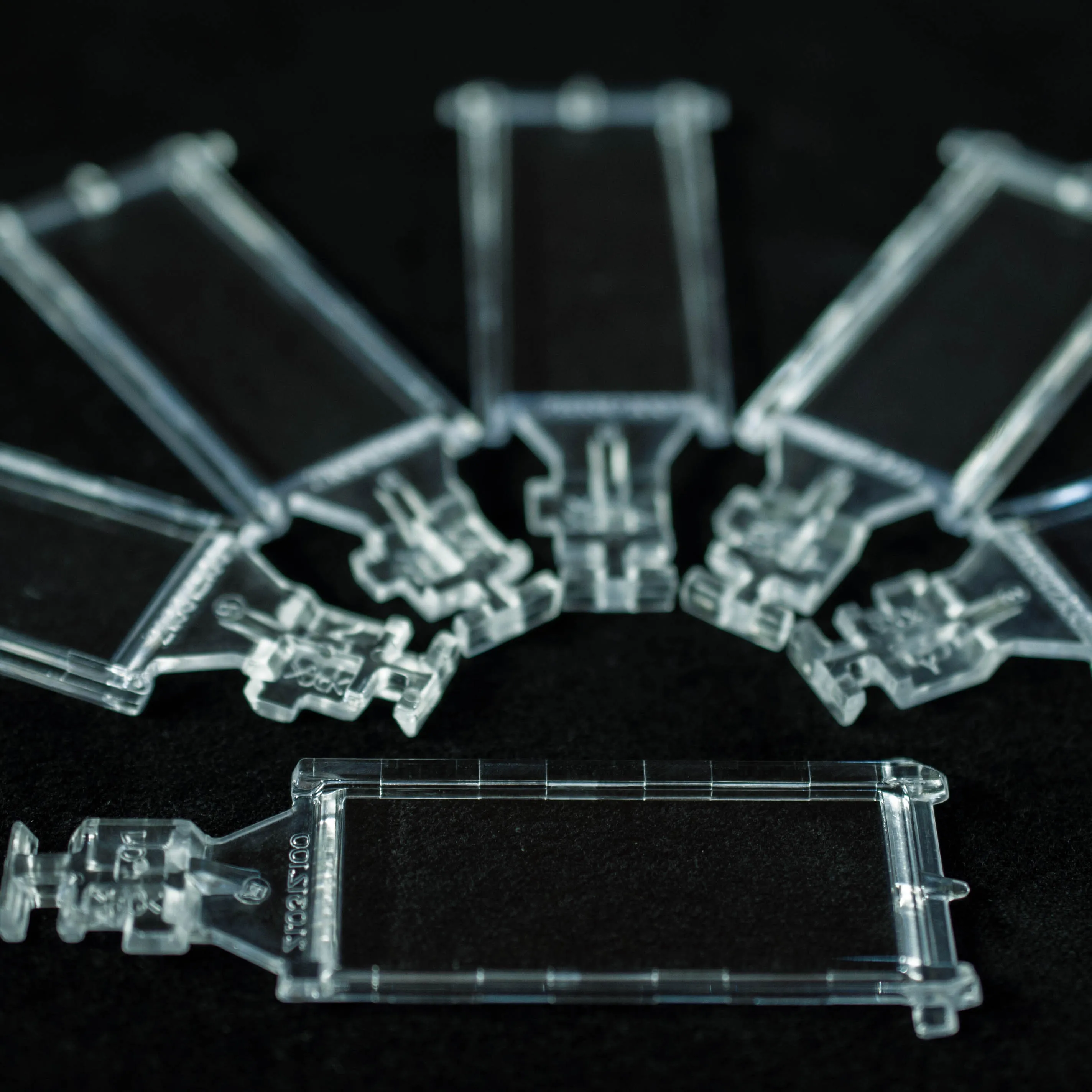

Along with manufacturing we also provide value added downstream processes. We have available manual and automated assembly services by purposed made machines and/or manufacturing cells with robots. We operate several in-house processes as ultrasonic welding, UV bonding and heat stacking processes.

For materials that are hydroscopic and require post manufacturing moisture treatment we operate a 33.2 m3 conditioning chamber.

Injection Moulders

At Forme Technologies we help to transforme your ideas into tangible and scalable products.

Forme Technologies is a plastics engineering and injection moulding firm with an unrivalled reputation for the delivery of quality. An agile, modern business, Forme Technologies is able to deliver exceptional quality prototypes and low-volume production runs of complex products with minimal turnaround times.

Servicing Melbourne, Australia, and the World

The cutting-edge of injection moulding

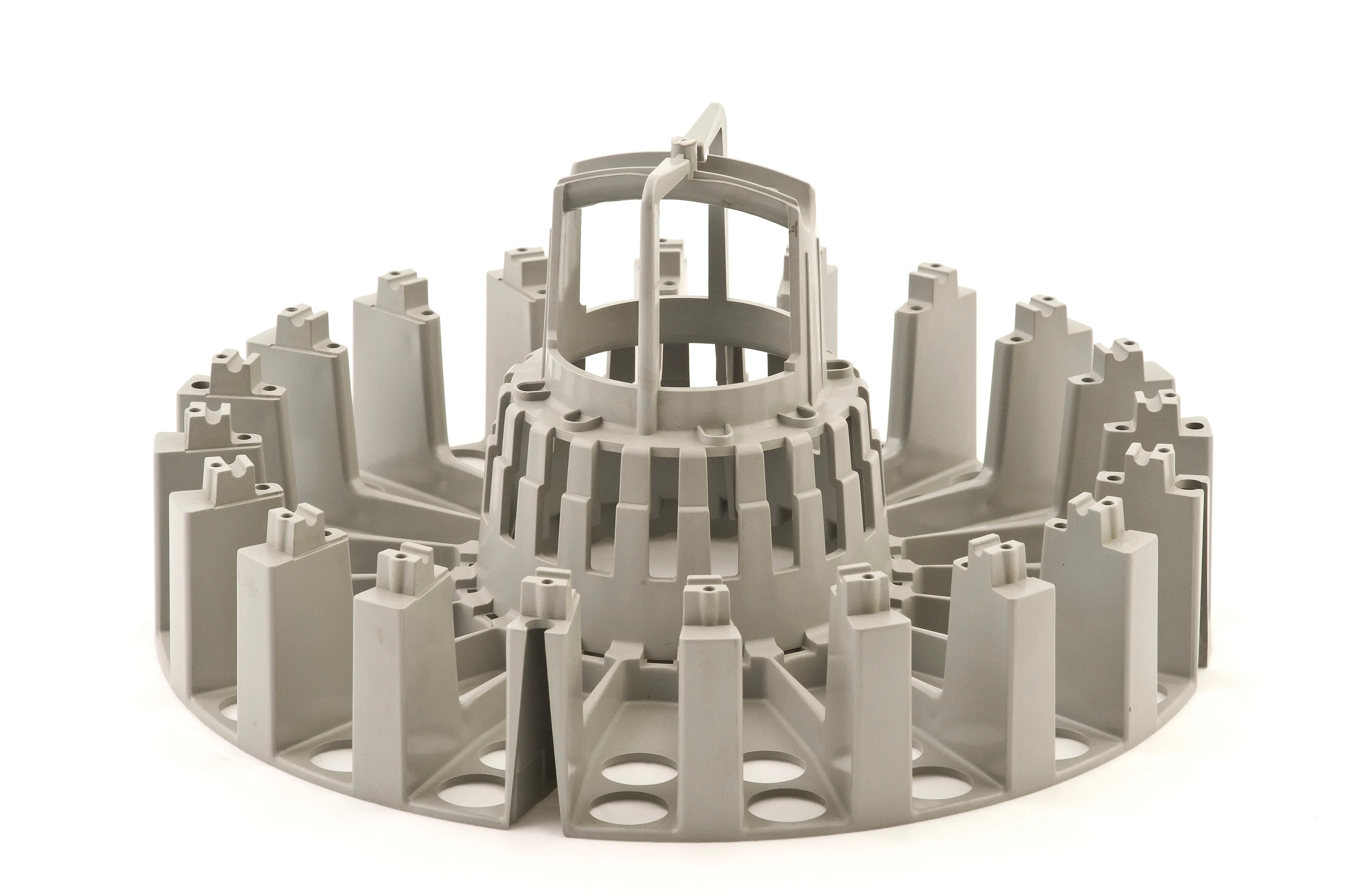

Forme Technologies believes strongly in the value of the continual improvement. As such, we invest heavily in new equipment and ongoing retraining and upskilling of our employees. Our facility operates 14 injection moulding machines in our ISO 9001 facility and 3 additional recent generation injection machines inside the Cleanroom of our second facility that runs under ISO 13485. Our machines of varying capacity and capabilities, range from 35 metric tonne machines suitable for small, intricate components to 450 metric tonne machines ideal for larger projects.

Latest Machinery & Equipment

Expertise Where it Counts

Ancillary equipment

Speak to Australia’s leading plastics manufacturers

Discuss your requirements with the team at Forme Technologies and discover why firms Melbourne, around Australia and, globally trust us to help them achieve their business goals.

Call us directly on +61 3 9782 3033 to learn more. Or click on the Get in Touch button to send us your enquiry.

FAQ's

Can you help me develop my idea into a manufacturable product?

Yes. We can translate your design into a manufacturable product. The earlier we can be involved in your product development the better. We work with you to define the product concept, investigate the manufacturing feasibility and propose the best combination of raw materials to meet your requirements, whether for mass production or batch manufacturing. We support you from the very beginning and help you through the entire concept process, to ensure your product is manufactured to the best quality.

What is 'art to part'?

This refers to the process we undertake to develop your product from an idea or concept right through to manufacturing and delivery. At the heart of this process, is an ethos of achieving the highest standard and providing exceptional customer service at every stage of the project.

What is Plastic Injection Moulding?

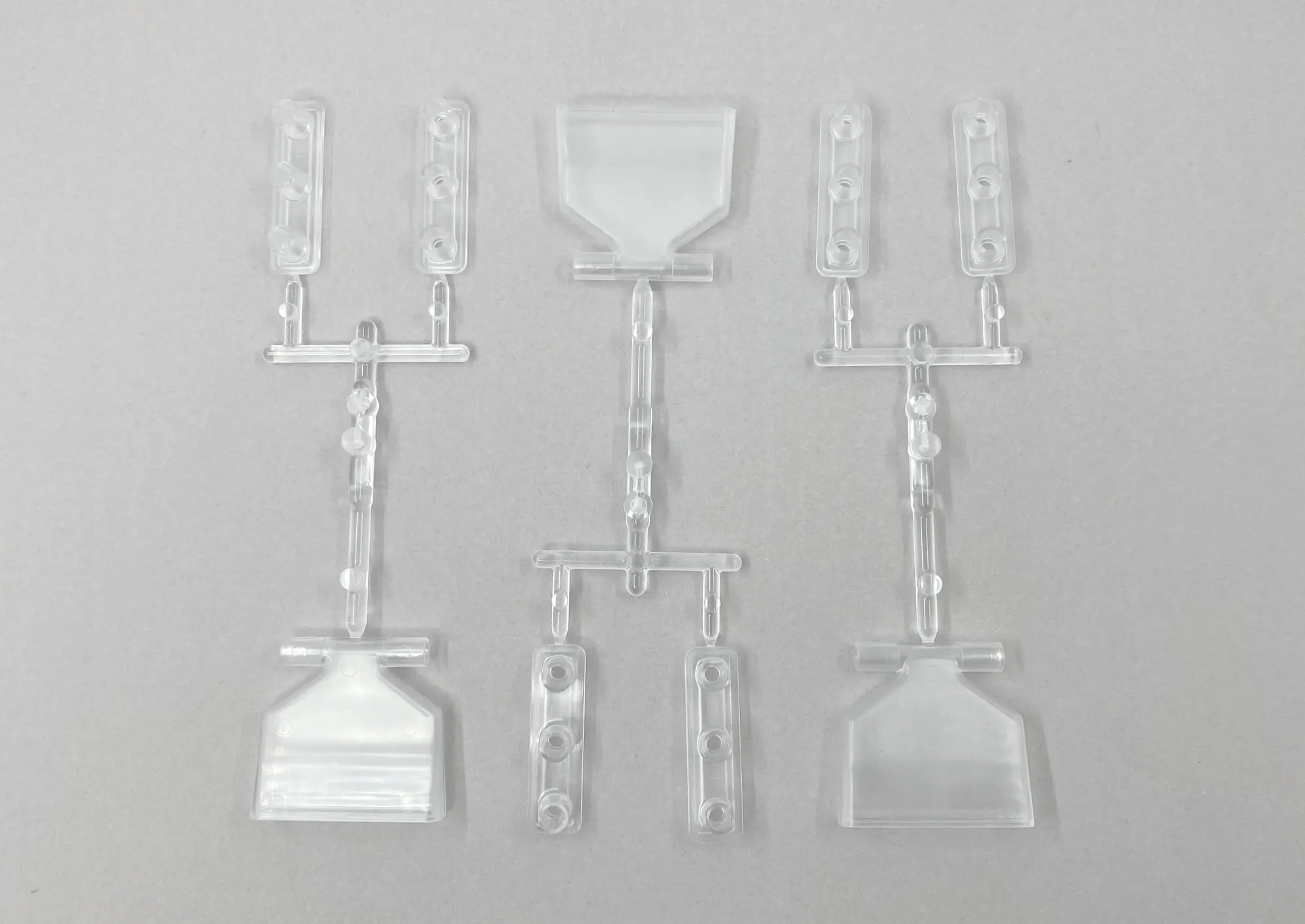

Plastic Injection Moulding is the manufacturing process we use to mass produce complex or simple plastic parts. Heated plastic is pressured into a mould to form different parts and products. The process requires a moulding machine where plastic granules are poured into a hopper and are then heated through the machine and injected into a pressured mould, often called a tool. For over 20 years, we have earned an excellent reputation in comprehensive plastic injection moulding services.

What is resolved at concept development stage?

The main goal is to ensure that the product can be designed, manufactured and delivered based on your technical and commercial requirements and specifications.

What is your expertise?

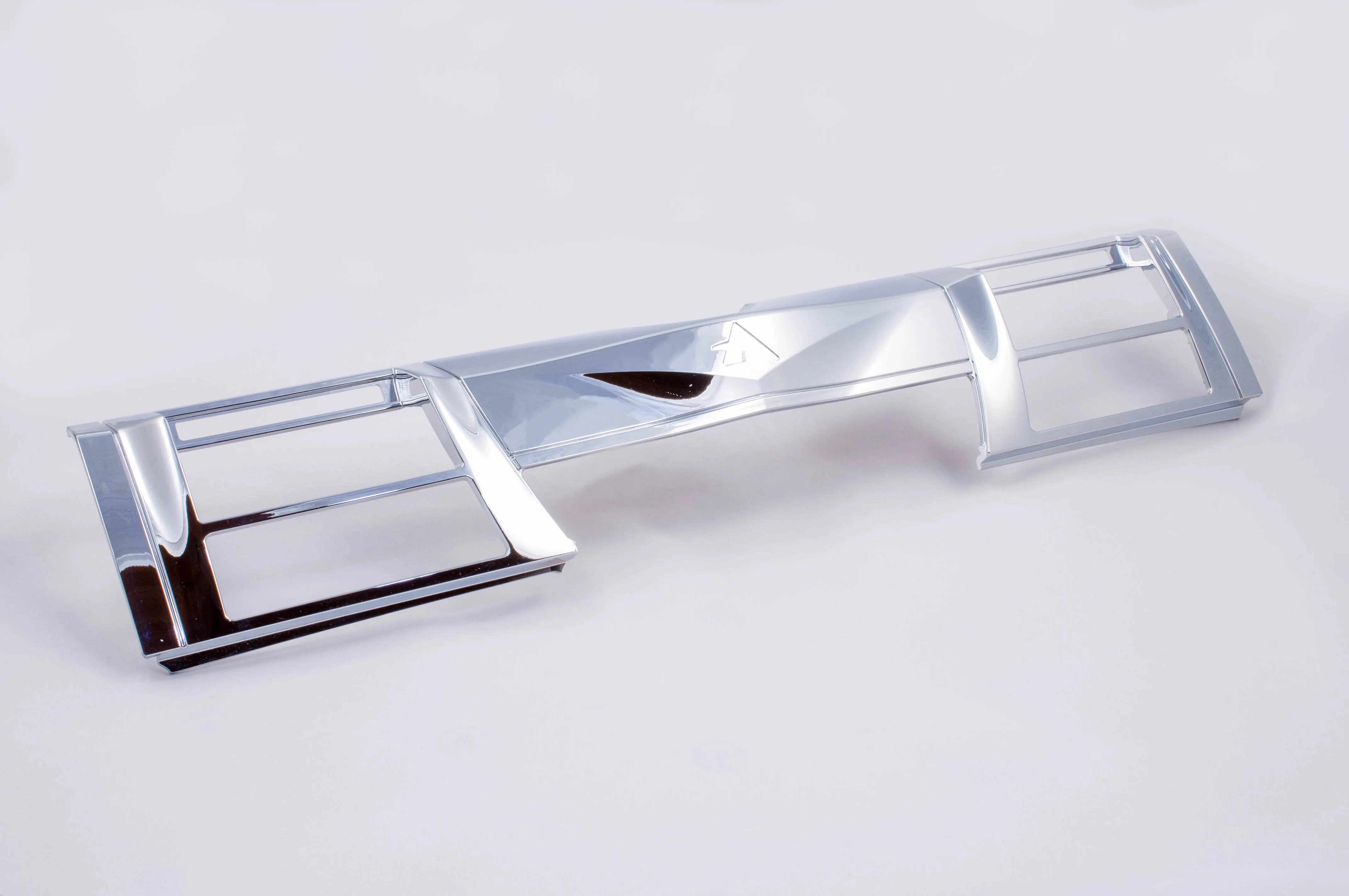

We manufacture plastic products/parts/components for the medical, electronic and automotive industry. We specialise in the production of complex, high-precision products as well as the production of simple components. Each product is tailored to your unique requirements. We can discuss potential ways of reducing product costs and time to market. We also offer packaging, storage and delivery solution.

What type of accreditation do you have as a business?

We are an ISO 9001 and ISO 13485 accredited business. ISO 13485 is the standard required for the manufacturing of medical devices.