About Forme Technologies

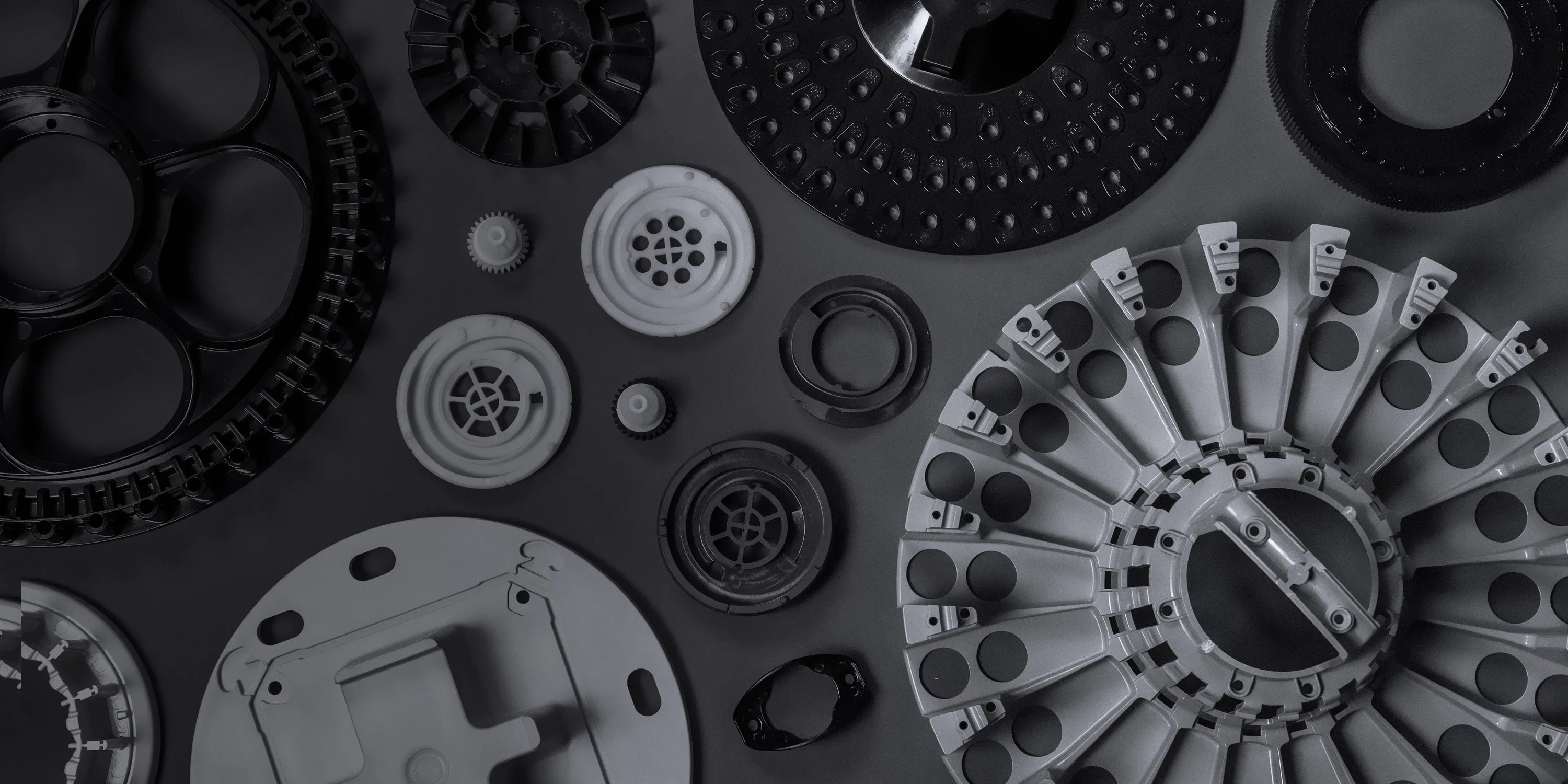

Forme Technologies is an Australian owned business. We are plastics moulding & precision tooling experts.

At Forme, we assist you from concept design and prototyping, product development, tooling, and manufacturing. We can make your products in our standard facilities, or for more stringent requirements in our brand new 220 sq metre ISO 7 cleanroom.

As we serve a wide variety of industries, we shape and align our processes to the specific requirements of our clients.

Specialised industries demand specialised solutions – the kind of precision and high-quality plastics engineering we have provided to Australian and International clients over 25 years.

QUALITY ASSURANCE

Forme Technologies’ reputation is built on achieving consistently superb quality on every project, no matter how unique, unusual or complex. This is why we are ISO 13485:2016 and ISO 9001:2015 certified in quality management and have a commitment to continuous improvement embedded throughout our strategic process.

RESOURCES

At Forme Technologies we continuously invest in our facilities to ensure that we meet the exacting standards of our clients, we work with the best engineering materials available and our high performing staff are extremely versatile across all manufacturing processes.

Our People

Our Facilities

Materials

CLEAN AND EFFICIENT PRODUCTION

At Forme Technologies we are fully committed to improving and preserving our environment. We believe that everyone has a part to play in order to effect a positive outcome. Forme Technologies has set about to be an example in our industry sector, striving to achieve reductions in green house gas emissions as well as improved productivity. In 2018, it was decided insofar as it was possible to switch our production requirements to renewable energy sources.

Due to our geographic location, solar energy provided the most effective solution both practically and financially. As part of our social commitment, we engaged local providers to execute this strategy, the investment of which provided a direct benefit to the local community. The solar energy system was commissioned in April 2018 and by the middle of May we were running for the most part on solar energy.

SECTORS

Medical Applications

Human safety is central to any medical product or device. This is what informs the numerous standards associated with medical devices and our compliance to these standards. We are highly experienced manufacturing products that need to meet stringent specifications.

Our ISO 13485 certification ease the regulatory path to market of products developed for the medical industry.

Technology Applications

Few people who use mobile phones, drones, tablets, gaming stations, coffee machines or any other device or product that has plastic enclosures or components ever consider how they were conceived, developed, and manufactured. That’s our job. We support our clients on the development of such components that are cost effective, work well and look good.

High Precision Applications

Besides medical devices and instruments components, we manufacture products that are used in a broad range of industries. We specialised on high end applications with demanding aesthetic, functional and dimensional requirements.

We produce parts for clients from the construction, sports, agriculture, maritime and consumer goods industries to name a few. As we serve such a variety of industries, we shape and align our processes to the specific requirements of our client.