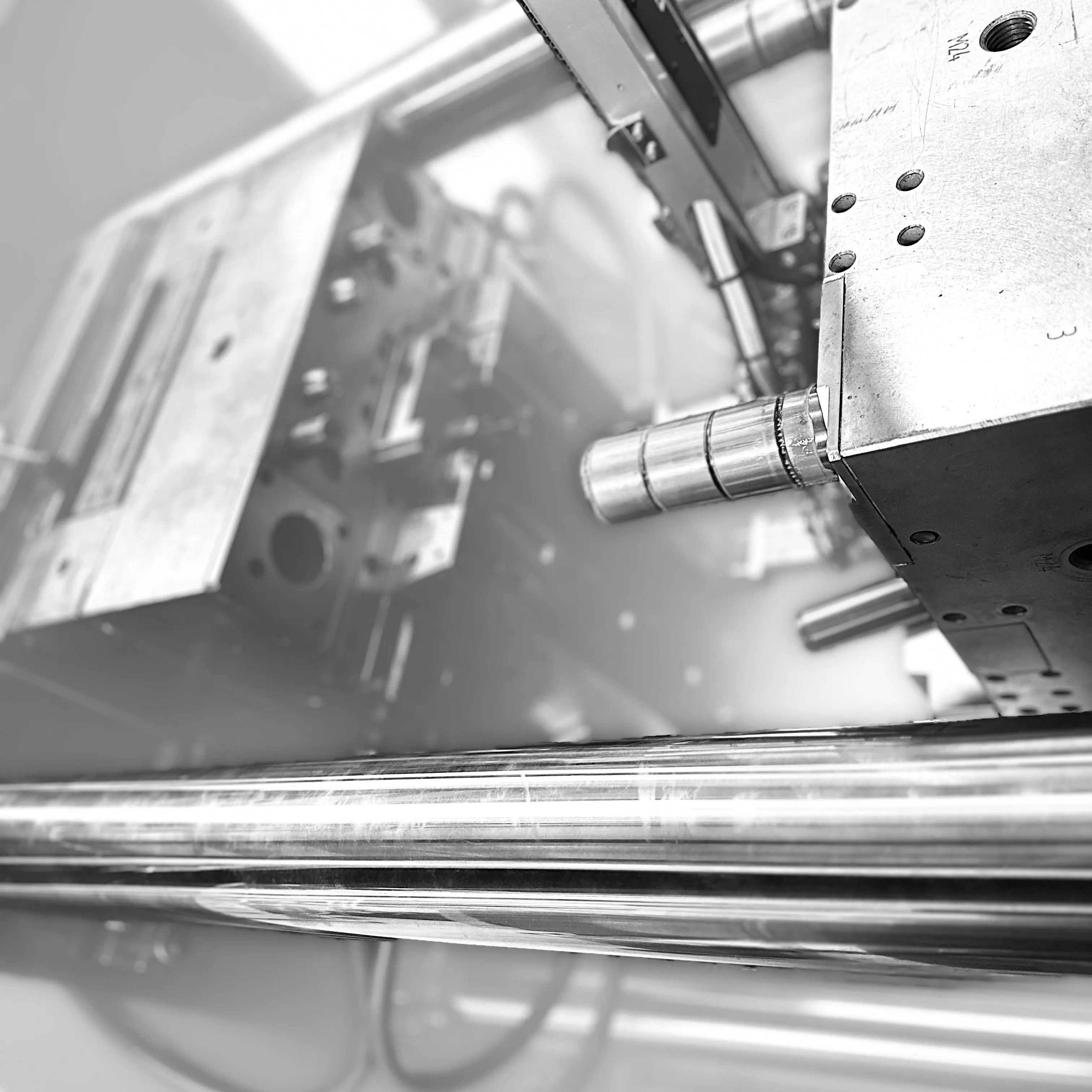

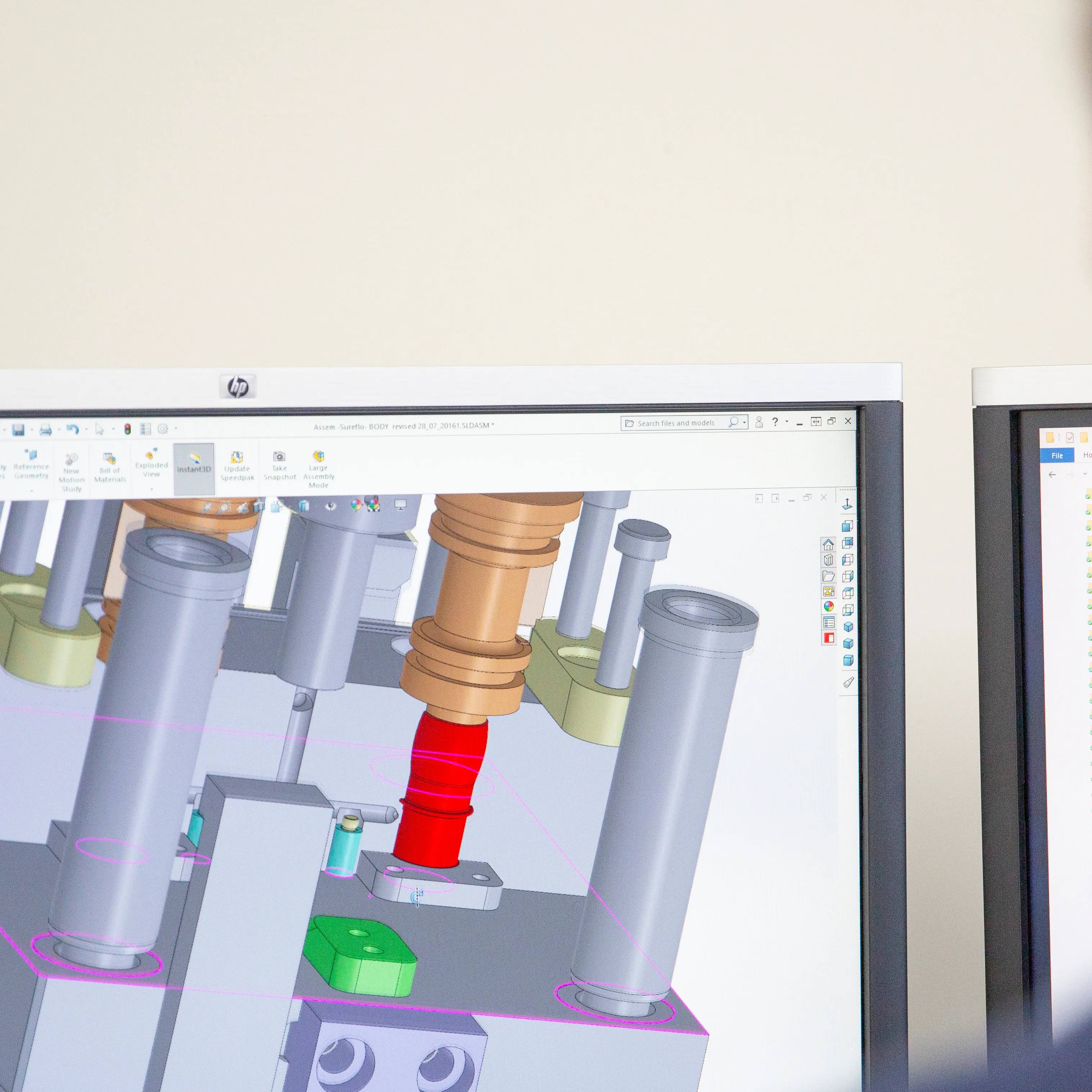

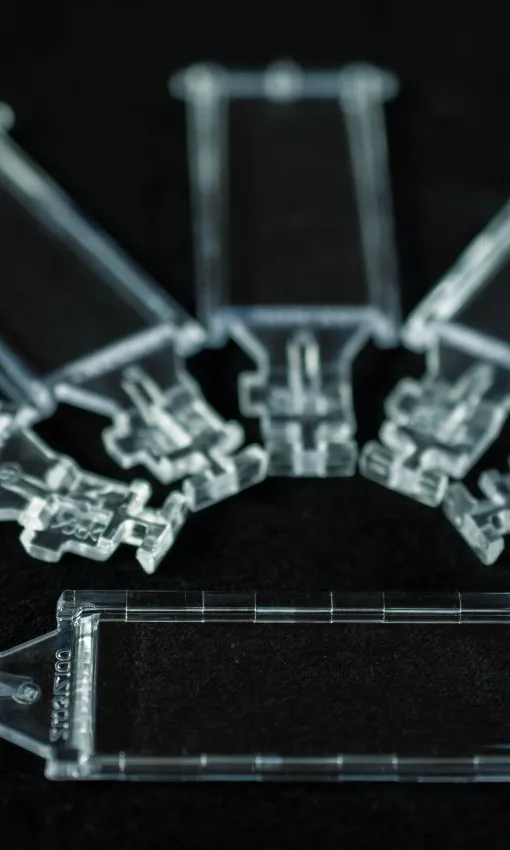

Forme Technologies are product development, precision tooling and plastics moulding experts. We can assist your product development journey from concept design through to prototyping, tooling, and manufacturing. Within our facilities we can provide for a regular production environment or for more stringent requirements our cleanroom manufacturing facilities can be utilised